12-13

12-13

The contact is one of the key parts of the switch apparatus. The main performance and life of the switch apparatus depend on the contact material to a great extent. Contact materials usually require good conductivity, low contact resistance, high anti welding performance, high arc erosion resistance and material transfer resistance. For vacuum contact materials, they also require small current cutoff value, high withstand voltage strength and high breaking capacity.

The microstructure of contact materials has an important influence on their macroscopic properties. The electrical properties of contact materials, such as resistance to welding, arc erosion and pressure resistance, are not only related to the composition of the contact materials, but also related to the grain size of the contact materials.

What are the common contact forms

There are three types of contact commonly used: plug-in type, bridge type and butt type. The plug-in contact is suitable for the contact without arc, and is often used as the plug-in connection of the outgoing line behind the switch board. The characteristic of this kind of contact is that it can pass huge short-circuit current, prevent the contact from springing open, and has the function of electric compensation.

Bridge contact is a kind of contact with double break point structure. Because a break point is added, the arc extinguishing device is simplified, but the double break point contact needs to be connected or disconnected at the same time. The contact is suitable for small capacity circuit breaker.

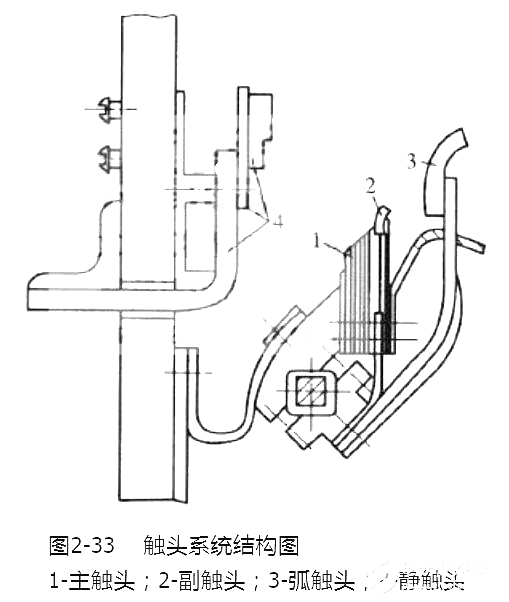

The butt contact has a pair of moving and static contacts, which is suitable for the circuit breaker with large current. In order to effectively prevent the current from damaging the contact, the butt contact is often made into three forms: single gear contact, double gear contact and three gear contact. Among them, the single gear contact has only one contact, that is, the main contact, which is suitable for the circuit breaker with small capacity; the double gear contact is composed of the main contact and the arc contact in parallel with the main contact, which is mainly used to break the arc and protect the main contact; the third gear contact adds a protective auxiliary contact between the main contact and the arc contact, so the breaking current ability is stronger.

The main contact passes through rated current under normal closing state and fault current under fault state. Because it needs enough electric stability, thermal stability and low contact resistance, the main contact is generally made of pure silver material. The arc contact is mainly used to protect the main contact. In the process of action, it closes before the main contact, and then breaks after the main contact, Therefore, the arcing always occurs on the arc contact, so the material for making the arc contact must be arc resistant and fusion welding resistant, usually made of silver tungsten alloy, copper tungsten alloy or brass, pure copper (red copper). In normal operation, the resistance of the arc contact is much larger than that of the main contact, so there is little working current. When the current is transferred from the main contact to the arc contact in the breaking process of the circuit breaker with large capacity, the voltage drop on the arc contact is too large, which may cause the tiny gap just generated by the main contact to be broken down and arced. Therefore, in the old products of circuit breaker, an auxiliary contact is added as the double protection of the main contact.

The working procedure of the third gear contact breaking the load is to first break the main contact, then the auxiliary contact, and finally the arc contact, so that the arc is extinguished between the arc contacts; when closing, the sequence is opposite, the arc contact is closed first, then the auxiliary contact is closed, and finally the main contact is closed. The structure of the contact system is shown in Figure 2-33.

Application of contact

Electrical contact is widely used in relay, contactor, load switch, medium and low voltage circuit breaker, household appliances, automotive appliances (horn, lamp, ignition) and other switch electrical appliances. Switching devices are widely used in the voltage / current of separate / closed circuit. Its reliability directly affects the reliable operation of the whole power system, and the electrical contact is one of the important parts of switching devices. Contact products are the "heart" parts of these products.